Operations management is a vital function in any supply chain. It is responsible for the planning, coordinating, and controlling of the resources and activities needed to produce a company’s goods or services. This blog post will explore the meaning and functions of operations management in detail.

What Is Operations Management in Supply Chain?

Operations management in the supply chain deals with producing and distributing goods and services. It includes the planning, scheduling, and controlling of all activities involved in the production process. The main objective of operations management is to ensure that goods and services are produced efficiently and effectively.

There are four main functions of operations management in the supply chain:

- Planning: This function involves developing plans to use resources to meet desired objectives efficiently.

- Scheduling: This function involves creating a schedule for when each activity should be carried out to meet desired objectives.

- Control: This function involves monitoring progress and making changes to the plan as necessary to ensure desired objectives are met.

- Improvement: This function involves constantly looking for ways to improve the efficiency and effectiveness of the production process.

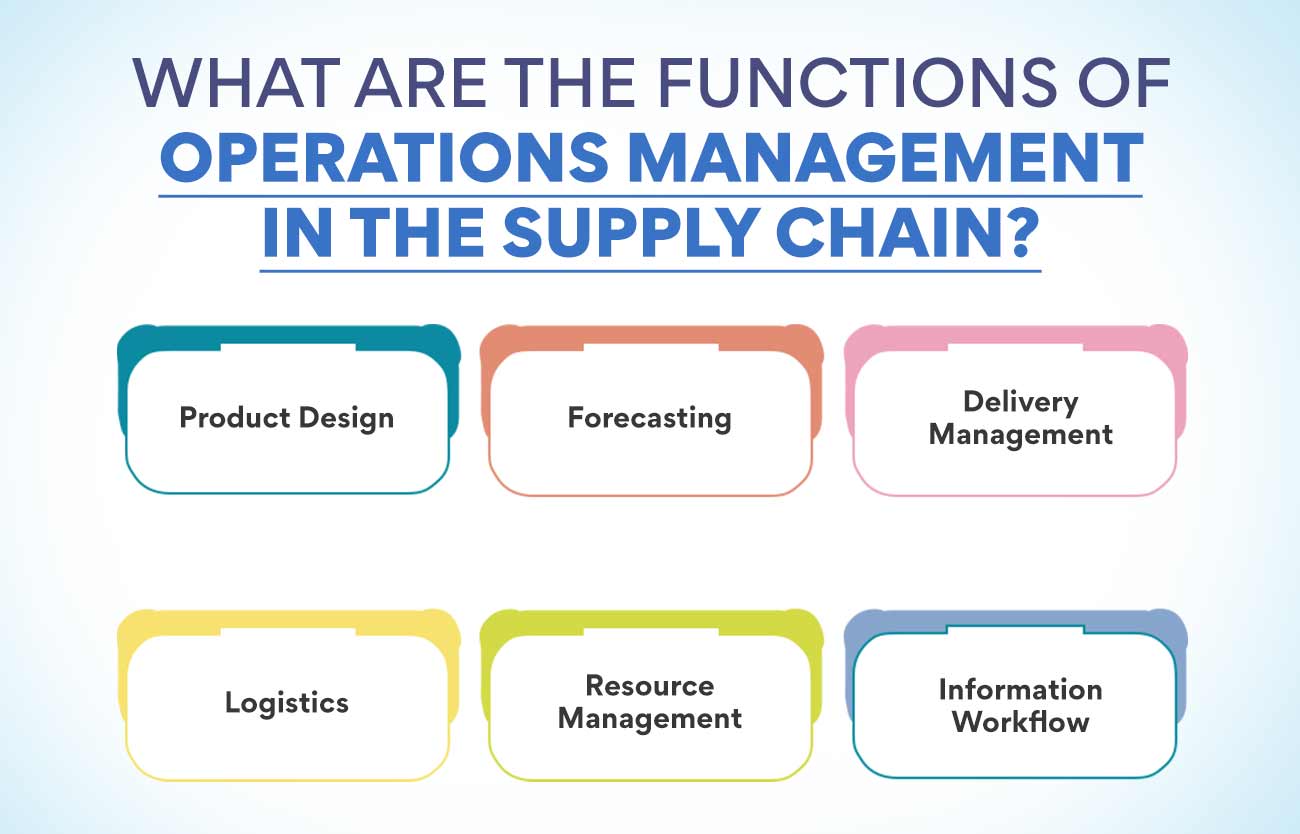

What Are The Functions of Operations Management in the Supply Chain?

Product Design

Product Design

Product design is creating a plan for the development of an object or system.

In supply chain management, product design involves developing goods and services to meet customer demand. It includes determining what products or services to offer, how they will be produced, and how they will be delivered to customers.

Product design is critical in operations management as it directly affects production decisions and costs. Poorly designed products can lead to production problems and excess inventory, while well-designed products can improve efficiency and profitability.

Product design aims to create a plan that meets customer needs while being feasible to produce. This planning process begins with market research to understand customer wants and needs. Once this information is gathered, engineers develop concepts for products that address these needs. These concepts are then evaluated for feasibility before a final design is chosen.

After a product has been designed, manufacturers must determine how it will be produced. This decision-making process is known as process planning and involves choosing the equipment, materials, and methods necessary to turn the product design into a reality. The goal of process planning is to establish a production plan that is efficient and cost-effective.

Forecasting

Forecasting is making predictions about future events based on past trends. In operations management, forecasting is used to plan for future demand, capacity, and inventory levels.

Various forecasting methods can be used, depending on the data type available and the nature of the forecast required. Some common techniques include trend analysis, regression analysis, time series analysis, and market research.

Forecasting is essential to effective operations management as it allows businesses to make informed decisions about future demand and capacity planning. By understanding past trends and using them to predict future demand, companies can avoid costly over- or under-production.

Also Read: What Is The Scope Of Operations Management?

Delivery Management

Numerous operational processes make up the supply chain, and each must be managed effectively to ensure the smooth and efficient running of the entire system. Delivery management is one such process, and it is responsible for ensuring that goods and materials are delivered to the correct destination, on time and in good condition.

To achieve this, delivery managers must have a strong understanding of the supply chain as a whole and the individual processes that make it up. They must also be able to efficiently communicate with all parties involved in the supply chain (e.g. suppliers, customers, transport companies etc.) to coordinate deliveries.

Good delivery management is crucial to any business that relies on a supply chain. Poor delivery management can lead to delays, lost or damaged goods, and unhappy customers – which may hurt the bottom line.

Logistics

Logistics manages the movement and storage of resources and materials. It is a critical component of supply chain management, ensuring that all resources and materials are moved and stored efficiently and effectively.

There are four key elements to logistics: transportation, inventory, warehousing, and order fulfilment. Every element must be managed effectively for the logistics process to succeed.

Transportation refers to the movement of resources and materials from one location to another. This can be done via land, air, or sea. Choosing the most efficient mode of transportation is important based on the type of resources and materials being moved.

Inventory refers to the resources and materials stored at any given time. It is essential to keep track of inventory levels to know when it is time to replenish stocks. Too much inventory can lead to storage problems, while too little can lead to production delays.

Warehousing refers to the facilities where resources and materials are stored. These facilities must be well-organized and secure to protect stocks from damage or theft. Order fulfilment refers to ensuring that customers receive the products they have ordered promptly and accurately. This includes processing orders, packing products, and shipping them out to customers.

Resource Management

In any business, resources must be managed to keep operations running smoothly. Supply chain management is no different. Resource management is even more important in supply chain management because of the need to coordinate so many moving parts.

Good resource management in supply chain management starts with understanding what resources are and when they are needed. It can be a challenge because demand can be unpredictable. However, there are plenty of ways to get a handle on demand:

- Use historical data to predict future demand

- Use market analysis to understand trends that might impact demand

- Use customer feedback to get a sense of what is required

Once you have a good understanding of what resources are needed, you can start to plan for how to acquire those resources. It might involve sourcing from suppliers, manufacturing products in-house, or using other methods. The key is ensuring you have the right mix of resources to meet demand without overspending.

Finally, it’s essential to monitor resource usage and adjust as needed. It includes tracking inventory levels, monitoring supplier performance, and making changes to production as necessary. By constantly monitoring and adjusting, you can ensure that your supply chain is as efficient as possible.

Information Workflow

The term ‘information workflow’ refers to creating, distributing, and using the information within an organization. It includes the collection and analysis of data, the decision-making process, and the communication of information throughout the organization.

Information workflow is a critical part of operations management in the supply chain because it ensures that all stakeholders have the required information to make informed decisions about the operation. It also allows for transparency and communication between different parts of the supply chain, which is essential for coordination and collaboration.

An effective information workflow will result in better decision-making, improved coordination and collaboration, and a more efficient supply chain.

What Is The Significance of Supply Chain in Operations Management?

The supply chain is a network of organizations that are involved in the process of creating and delivering a product or service. The supply chain includes suppliers, manufacturers, distributors, retailers, and customers.

The supply chain is essential to operations management because it determines how resources will flow through the organization. Operations managers must plan and coordinate the activities of the supply chain to ensure that the right resources are available at the right time and place.

Supply chain management is a field of operations management that focuses on managing the flow of materials and information among suppliers and customers. Supply chain managers are responsible for coordinating the supply chain’s activities to optimize efficiency and effectiveness.

The significance of the supply chain in operations management lies in its ability to impact all aspects of operations. A well-managed supply chain can improve efficiency by reducing waste and maximizing resources. It can also improve quality by ensuring that only the best products or services are delivered to customers. In addition, an effectively managed supply chain can improve customer satisfaction by providing timely delivery and responsive customer service.

How Supply Chain In Operations Management Work?

In operations management, the supply chain is the process that takes inputs of materials, information, and finances from suppliers and converts them into outputs of goods and services for customers. The supply chain includes all the steps from raw material procurement to finished product delivery.

Operations management aims to ensure that the supply chain runs smoothly and efficiently so that goods and services are delivered on time and within budget. To do this, operations managers need to plan and coordinate all activities involved in the supply chain, including production, transportation, warehousing, and inventory management.

Operations managers must also be able to handle any disruptions that may occur in the supply chain. For example, if a supplier is late with a shipment of raw materials, the operations manager will need to find a new supplier or make other arrangements so that production can continue on schedule.

What Are The Challenges Associated With Supply Chain In Operations Management?

The challenges associated with the supply chain in operations management are manifold. The most significant challenge is the management of disparate and often conflicting objectives of the various stakeholders involved in the supply chain. Another challenge is the increasing complexity of supply chains, as they often span multiple countries and involve many suppliers, manufacturers, distributors, retailers, and customers. This complexity makes it difficult to manage the flow of goods and information across the supply chain. Additionally, the volatile nature of markets and customer demand can make it difficult to forecast accurately and plan accordingly.

Also Read:

What Are The Trends In Supply Chain for Operations Management?

The supply chain for operations management is constantly evolving and changing. It means that the trends in this field are always changing as well. Some of the latest trends include:

- The use of big data and analytics to improve decisions and optimize processes.

- A shift towards more collaborative and networked supply chains.

- An increased focus on sustainability and ethical practices throughout the supply chain.

- A move towards more agile and adaptive operations management practices.

- Greater emphasis on customer experience and engagement throughout the supply chain.

What the Future Awaits For Supply Chain in Operations Management?

The future of operations management in the supply chain is shrouded in a great deal of uncertainty. Nevertheless, certain trends will shape the domain in the coming years. These are some of the most important:

The continued growth of e-commerce will likely profoundly impact operations management in the supply chain. As more and more businesses move their sales online, the need for efficient and effective operations management will become even more pronounced. In particular, managing inventory levels and ensuring timely delivery will become increasingly important.

The globalization of business is another trend that will likely impact operations management in the supply chain. As businesses expand their reach into new markets, they will need to manage their supply chains across multiple geographical regions effectively. It will require a greater focus on coordination and communication between different parts of the supply chain.

Finally, sustainability is likely to become an increasingly important consideration for operations managers in the supply chain. With pressure mounting on businesses to reduce their environmental impact, there will be a need to develop more efficient and sustainable methods of managing resources throughout the supply chain.

Conclusion

Operations management in a supply chain is critical to ensuring that goods and services are delivered on time and in the correct quantities. Businesses can increase efficiency, reduce costs, and improve customer satisfaction by streamlining operations and improving communication between different parts of the supply chain. If you’re responsible for managing a supply chain, make sure you’re familiar with the basics of operations management to keep things running smoothly.

Check out the course Advanced Certificate in Operations, Supply Chain and Project Management which covers various topics related to operations management in the supply chain. It benefits those who wish to understand better how operations are managed in a supply chain setting. The course covers planning and control, inventory management, quality assurance, and project management.

More Information:

Operations Management: Definition, Examples, and Strategies

Decision Making in Operations Management: Key Points

Operations Management in Hospitals – Know Crucial Functions

What are the functions of production and operations management